How To Troubleshoot Air Conditioner Compressor

A single best article explaining all possibilities of a bad compressor

-

How to Troubleshoot Air Conditioner Compressor

-

Why My AC is So Loud/ Noisy

-

How Do I Add Refrigerant to My Compressor

-

Gas Furnace Troubleshooting

-

Furnace Order of Operation

How To Troubleshoot An Air Conditioner Compressor

So you walk into the customers home and they say that the AC was working just fine yesterday but now it only blows warm or room temperature air. So I confirm what customer told me, there is room temperature air coming out of the supply events running so I don’t start checking anything there yet.

The next thing I want to do is head to the outdoor unit and check to see if it’s running before going anywhere check out the contactor to see if anything is shorted to ground you can do this by putting your meter setting on continuity check put one meter lead on the left terminal on the load side of the contactor and one of them to ground: do you have any continuity there? if you have continuity at either of these terminals to ground then something is shorted to ground now you just have to find it, it could be any of the high voltage wiring, the contactor, the capacitor or start capacitor, the condenser fan motor or the crankcase heater.

First I usually just do this with the wires at the service panel still connected to the compressor if I see something screwing then I’ll make an effort to actually go in and check the terminals themselves at the compressor.

First get your wires that lead to the compressor together.

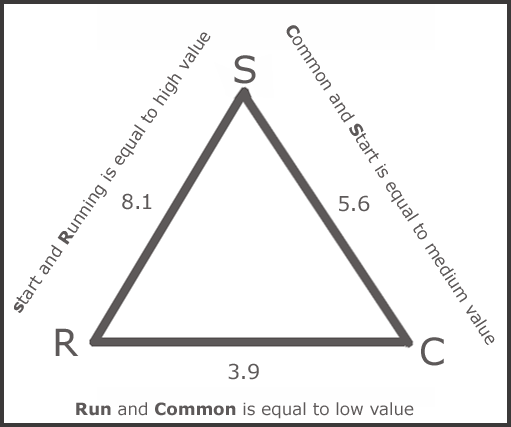

Check your Ohms reading between Common(C) to Start(S), C to Run(R) and Start to Run.

Without going into crazy details, generally you’re going to see the resistance.

Between common and start will be a little bit higher than common to run. The total of those two numbers is what you’ll read between start and run so if you had 5.6 ohms between common and start and 3.9 between C to R then you should have about 8.1 ohms between S and R.

If common to start and start to run is OL then you have an open start winding, same on the other side if C to R and R to S is OL you have an open run winding.

I’m trying to stress there and here because Between start and common but when you test between start and run it’s not open it’s likely it’s just the internal overload switch that’s open let the compressor cool off and retest it before condemning the compressor you hate to charge a customer for a Pressure when it was just overheated due to another issue when the windings on the compressor are expected though the Hermetic compressor will need to be replaced her medic compressors like the ones that we work on in residential HVAC are sealed so we can’t get into them to make any repairs so what are the whinings are good go check the breaker at the main panel a breaker has three positions on off and tripped is it trip to the middle position try resetting the breaker by flipping it to off and then back to on again Breakers trip to the Heat and excessive tripping resistance is a source of heat High current is a source of heat hot outdoor temperatures beating down on the southwest side of the house can be a big source of direct heat to The Breakers inside the panel if the breaker trips immediately you’ve got an electrical short to ground somewhere if the breaker trips after running for anything longer than immediately you could have excessive current too small of a breaker or fuse High indoor return air on a scorching hot day which will put a ton of stress on the outdoor unit a dirty condenser coil if an outdoor unit can’t draw air in across its coil it all overheat the AC a breaker that trips several times can get weaker and weaker until it takes less heat to trip it so that’s a possibility to keep in mind if the breaker is not tripped turn it off and check the fuses at the disconnect between each end of the fuse if either of them is Ol it’s done its job and protected the circuit but it’s also the reason that the AC isn’t starting should we just replace the fuse or reset the breaker and move on to our next call no way as an 8-track technician aren’t you dying to find out why the breaker is tripping maybe it’s a locked rotor a locked rotor most commonly happens at the beginning of the season when it hasn’t been running for a while put an implant on the common wire while it’s trying to start you’ll see the amps Skyrocket Beyond its LRA, In this instance I let the customer know that I want to try a hard start kit to see if it’ll give it that extra little kick it needs to get going.

If it doesn’t work I’ll take the start kit back but if it does work they’ll need to buy the start kit and at that point they just need to understand something their compressor is on borrowed time. Something that you can check next is the line voltage at the contactors load side, of course, this is with a call for cooling at the thermostat.

Suppose you’re 240 volt system reduces to less than 200 volts when it’s trying to turn on. Figure out what’s going on there, is it the wire size? a bad contactor? But if these are good to go, let’s ohm out the compressor

The next step would be to bypass the compressor, Another thing that you can try is removing the wires from the compressor altogether and just run the outdoor unit with the fan only, if the fan works, great. You can move on You know it’s not the fan tripping the breaker if the fan isn’t working,troubleshoot it.

You may have to replace the fan motor, cool down the compressor until the units ready to run again, and retest the system. Rarely do We ever find that the condenser fan motor and the compressor will have gone bad on the same day but it can happen.

Next, lets check internal overload. Let’s assume that we do have good power to the condenser’s contactor and on to the fan motor and compressor but the compressors not working you can tell that the fan works because its spinning just fine and even has good amp draws.

let’s check and make sure that the compressor has an overheated and shut down on internal overload before we condemn this thing check the resistance by switching the meter to ohms and check between the common and start winding and then do the same with the common and run windings does the meter show and open circuit on either one of those tests but not between the start and run terminals, if so, we should let the compressor cooldown and retest it.

Letting it compressor cool down on 100° day can take a long time, To expediete the process, we can use a garden hose to pour cool water over its top and then let it run down the sides of it evenly there’s literally a switch inside of that compressor that will open or close depending on whether it’s safe to run or not kind of like a self-destruct prevention switch

So why did the compressor internal overload switch open in the first place?

A bad capacitor or hard start kit can cause the compressor winding to overheat or just not start at all.

Before we diagnose a bad compressor we should make sure that our capacitors are good. Sometimes it could be a bad hard start kit, just bypass the hardstart kit (by removing it from circuit).

Bad valves are you sure something I hear a technician say a lot is that the compressor has bad valves well today’s scroll compressors don’t have valves they do have bearings that can go bad but valves were an issue with reciprocating compressors if you have decent refrigerator

remember you’re going to see higher amp draws on a compressor the hotter it gets outside but if that

Things like contaminated refrigerant the only thing that should be inside the refrigerant lines are oil and version refrigerant if moisture air does or anything else gets inside the lines will become contaminated contaminated refrigerant will become acid over time this creates

==================

For Gets outside but if a compressor is running anywhere near its rla and the refrigerant charges good that compressor is hurting That you’re working on it could have bad bearings not bad valves some other things to check so many things can happen to a compressor to cause it to fail not only do you have to diagnose that it’s a bad compressor but you also have to figure out why it’s not working things like contaminated refrigerant the only thing that

it not some other things to check so many things can happen to a compressor to cause it to fail not only do you have to diagnose that it’s a bad compressor but you also have to figure out why it’s not working seems like contaminated refrigerant the only thing that should be inside the refrigerant lines are oil and virgin refrigerant if moisture air dust or anything else gets inside the lines will become contaminated contaminated refrigerant will become acid over time and either way at the protective coating on the stator windings that make the compressor rotor spin what’s the protective lining has been deteriorated will become exposed and fail in a big way situation where the compressor shorts directly to ground a wire has now created continuity with the compressor’s body and completely Burns and charged anything inside of it the oil refrigerant and the compressors components will all become black and lined with food burnt wiring if the terminals attached to the compressor you can imagine the arcing that occurs across the gap of those Loosely stranded wires retest the system

Thank you so much for an amazing article. it really helped alot